Generally supplied annealed to hb 231 max.

A2 tool steel heat treat process.

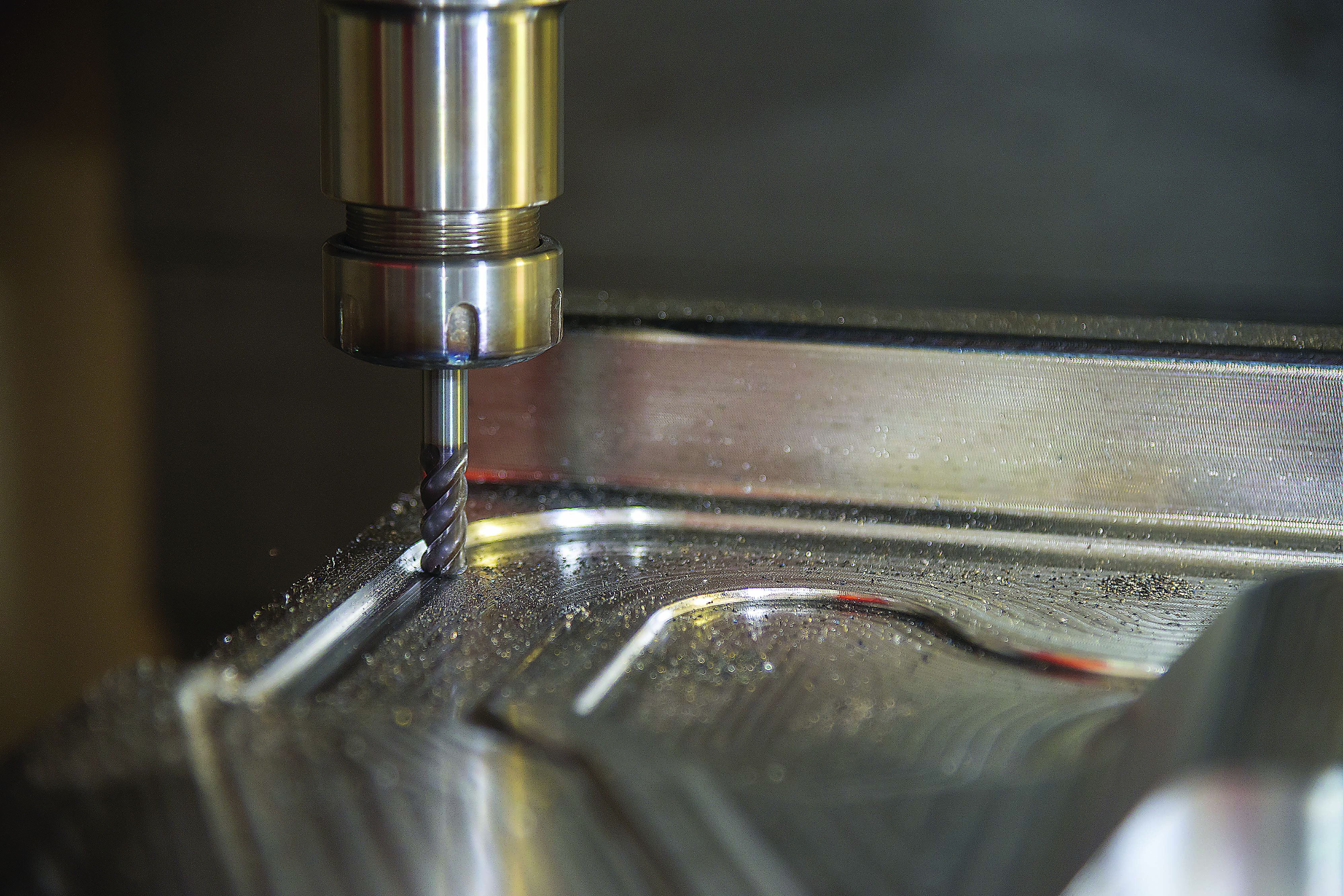

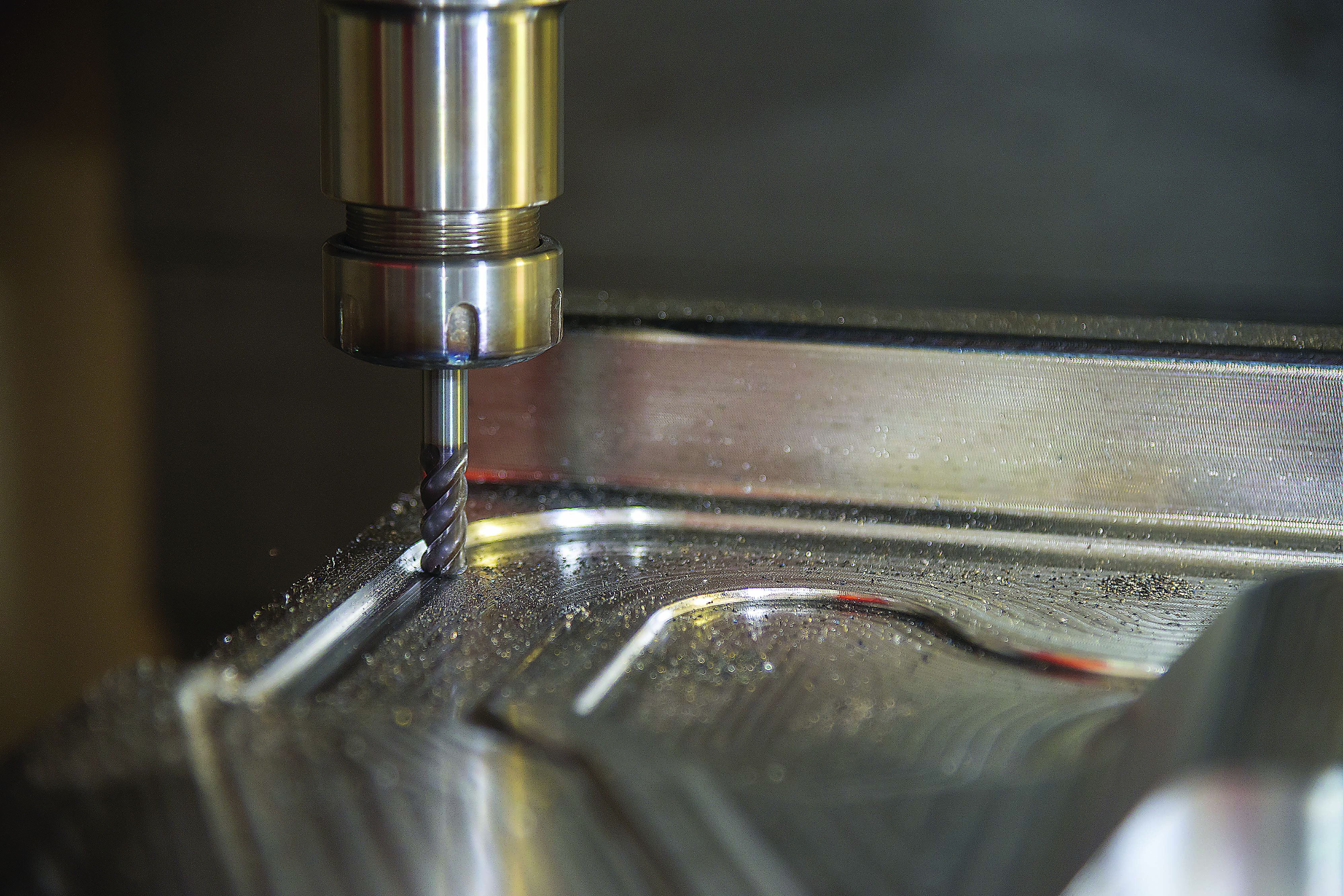

A2 tool steel is an air hardening cold work chromium alloy die steel that is preferable to o1 tool steel in applications requiring greater size stability machinability and safer hardening.

Like d2 it is incredibly resistant to distortion during heat treating and is moderately machinable and grindable.

It is heat treatable and will offer a hardness in the range 57 62 hrc.

This widely used tool steel has low distortion in heat treatment good machinability good toughness for severe service high abrasion resistance and deep.

The wear resistance properties and cost place a2 between that of o1 and d2 tool steel making it a good all purpose grade for many applications.

Soak at temperature for approximately two hours and cool slowly in the fur nace.

A 5 chromium steel which provides high hardness after heat treatment with good dimensional stability.

Most tool steels grow between about 0 0005 and 0 002 inch per inch of original length during heat treatment.

Stress relieving when heavy machining cuts are employed the resultant stresses may be relieved by heating the material to 1200 f to 1250 f for one hour and cooling in still air.

It s highly wear resistant and moderately tough.

The steel is composted of 1 percent carbon 3 percent silicon 6 percent manganese 5 3 percent chromium 1 1 percent molybdenum and 2 percent vanadium.

A2 tool steel properties.

A2 tool steel is a 5 chromium medium alloy cold work tool steel possessing sufficient hardenability to be air hardened to 60 rc surface hardness level with good depth of hardening.

A simplified guide to heat treating tool steels when we consider that the greater overall costs of most tools and dies are incurred prior to heat treatment and further that proper heat treatment is critical to the successful application of tooling this so called hardening process is placed in it s proper perspective of importance.

A2 steel is an air hardening cold work tool steel.

A2 air hardening tool steel annealing heat uniformly to 1650 f.

The prefix a in the name designates it as an air hardening steel.

The heat treat process results in unavoidable size increases in tool steels because of the changes in their microstructure.

A2 is also an air hardening tool steel but includes less than half the chromium 4 75 5 50 and a bit less carbon 0 95 1 05 than d2.