Powder blasting or abrasive jet machining is a technique in which a particle jet typically al 2 o 3 particles of 3 30 μm is directed toward a target for mechanical material removal.

Abrasive water jet machining pdf.

Abrasive jet machining definition.

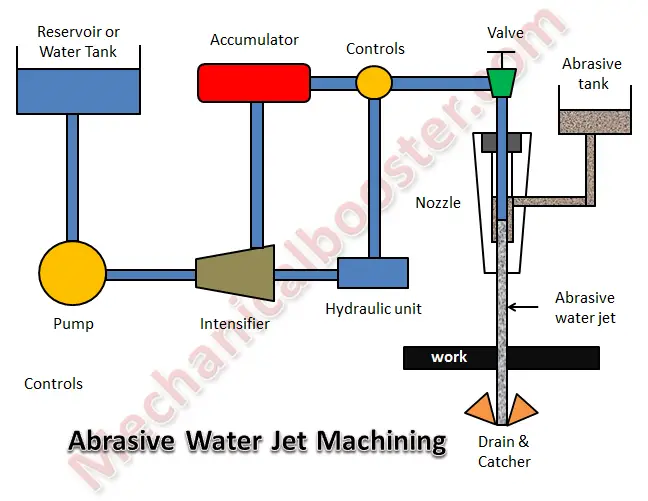

It uses water jet working as a tool to cut the metal.

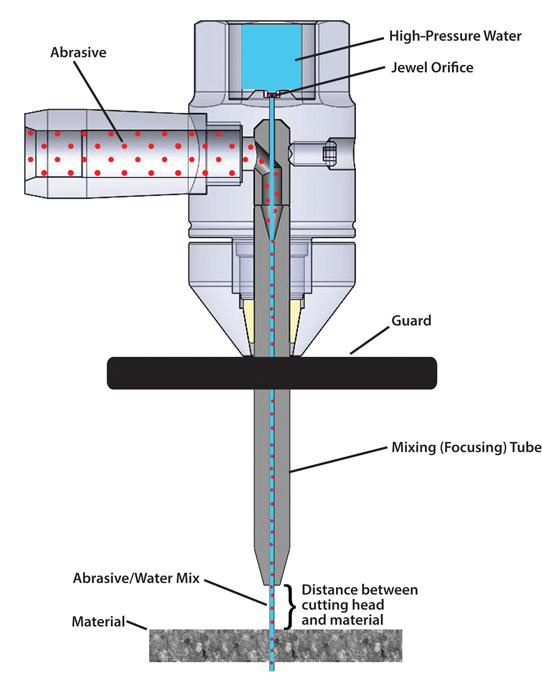

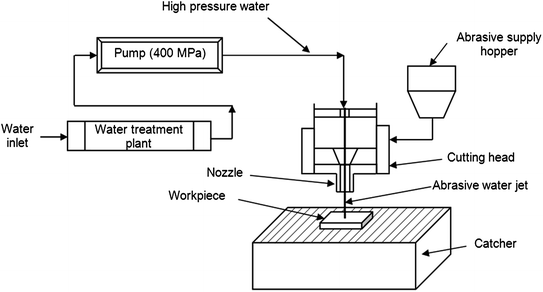

Two types of cutting let us take a closer look at the basics of the two waterjet cutting methods.

Abrasive water jet processes.

These high velocity abrasive particles remove metal by brittle fracture or erosion from work piece.

Water jet cutting a technology on the rise october 2010 page 7 5.

30 8 3 waterjet and abrasive waterjet machining.

Extremely powerful abrasive waterjets are capable of cutting through 3 inch 76 mm tool steel at a rate of 2 inches per minute 850 μm s 1 10 inch.

It is a fast.

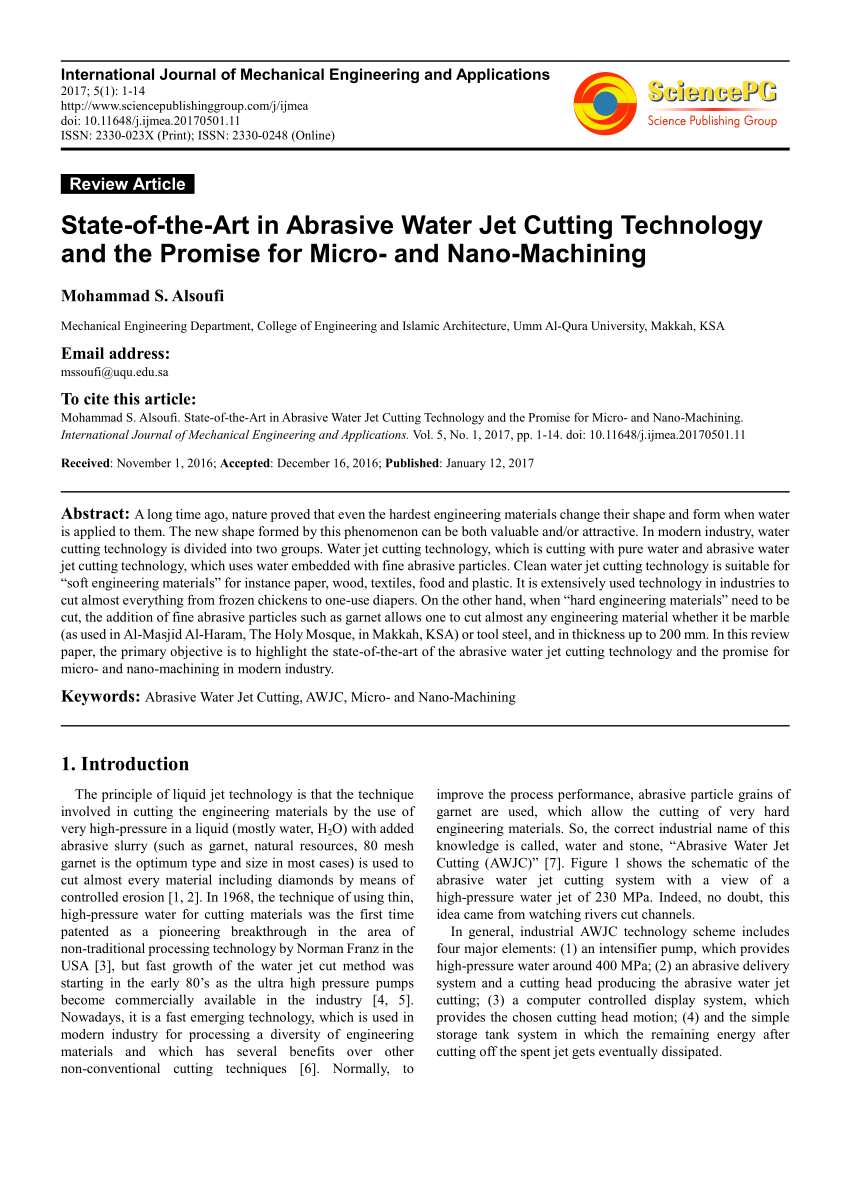

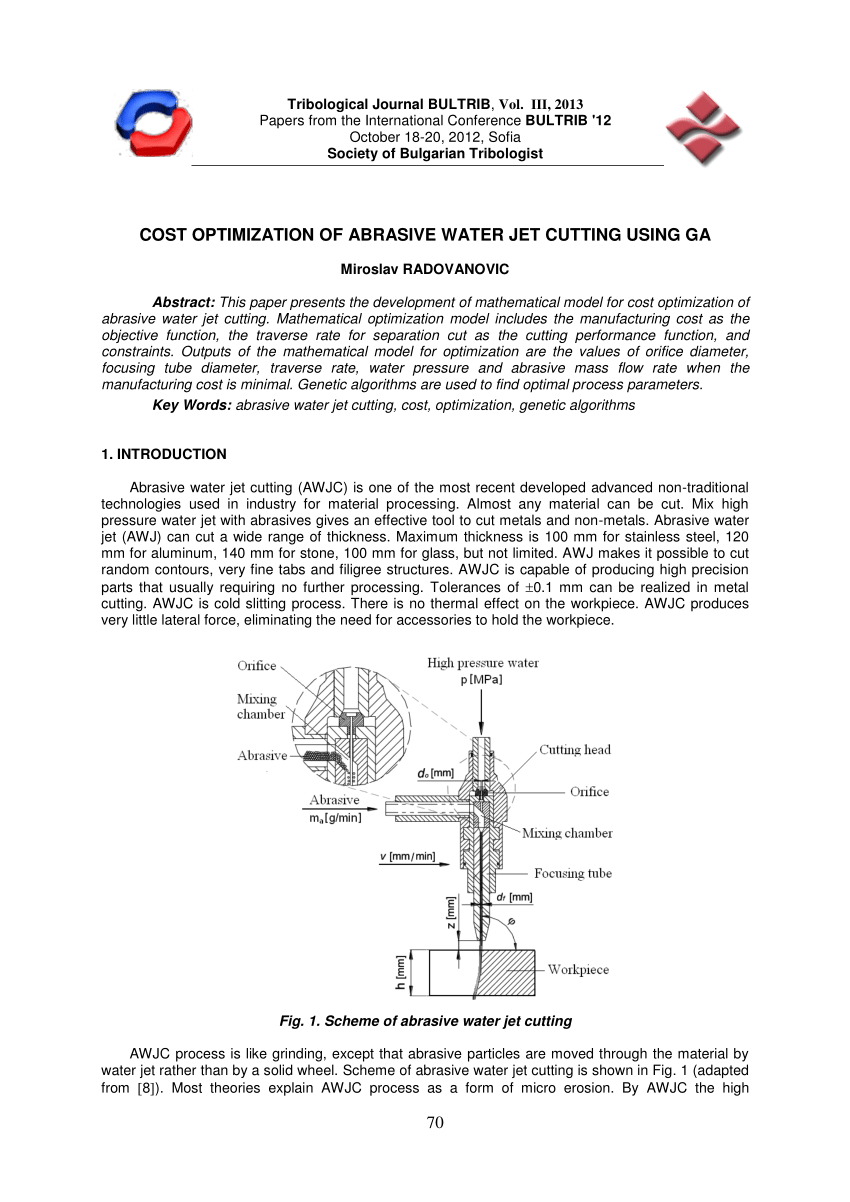

Water jet machining uses water mixed with abrasive materials projected with high pressure typically 0 7 mpa and focused on the workpiece.

In smithells metals reference book eighth edition 2004.

Water jet machining wjm also called water jet cutting is a non traditional machining process in which high velocity jet of water is used to remove materials from the surface of the workpiece wjm can be used to cut softer materials like plastic rubber or wood.

Today we will learn about water jet machining and abrasive water jet machining principle working equipment s application advantages and disadvantages with its diagram.

In order to cut harder materials like metals or granite an abrasive material is mixed in the water.

Manufacturers are increasingly turning to waterjet and abrasive waterjet machining in their quest for productivity and quality.

Abrasive jet machining is a non traditional machining process which is mostly used in machining of hardened metals.

Typically the inlet water is supplied at ultra high pressure.

Used to cut soft materials such as foam rubber cloth paper food products etc.

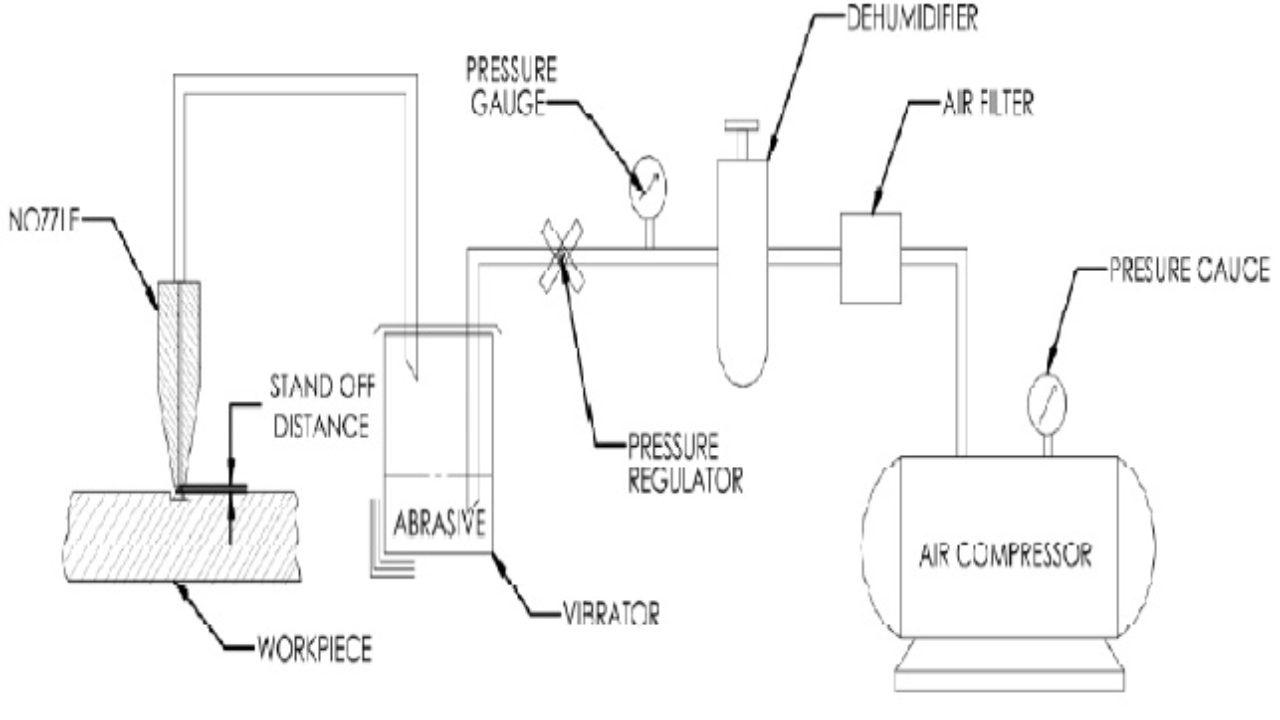

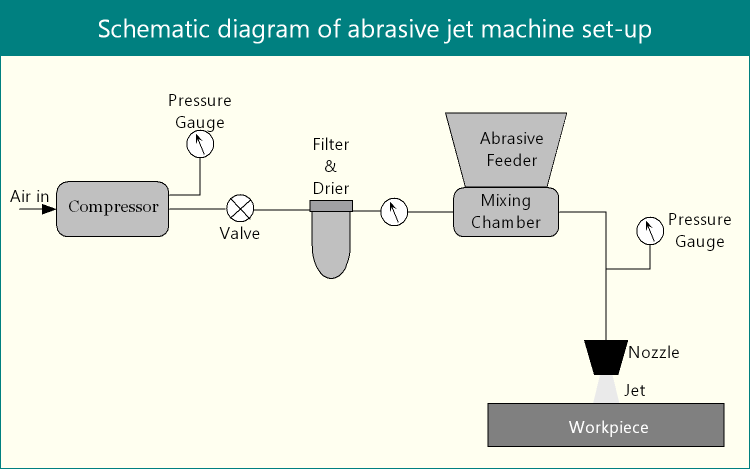

The abrasive jet machining is the process of impinging the high speed stream of abrasive particles by high pressure gas or air on the work surface through a nozzle and metal removal occurs due to erosion caused by high speed abrasive particles.

In this machining process a focus stream of abrasive particles are forces to impinge on work piece at high velocity.

It is one of the most famous non traditional machining process because it is environment friendly.

Principle of water jet machine this process works on the basic principle of water erosion.

Water jet machining invented 1970 a waterjet consists of a pressurized jet of water exiting a small orifice at extreme velocity.